I'm having issues with the extruder. The symptom is that the extrusion stops after the first layer (or so) because the

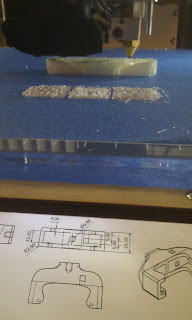

hobbed bolt of the extruder has worn the filament away and it can't get a grip on it. The picture below shows two locations where the normal grip zipper pattern is interrupted by a worn spot.

|

| Worn spots on the filament where the hobbed bolt has ground it away. |

So, how to debug this problem?

Another effective technique is to explain your code to someone else. This will often cause you to explain the bug to yourself. Sometimes it takes no more than a few sentences, followed by an embarrassed "Never mind, I see what's wrong. Sorry to bother you." This works remarkably well; you can even use non-programmers as listeners. One university computer center kept a teddy bear near the help desk. Students with mysterious bugs were required to explain them to the bear before they could speak to a human counselor. ~Brian Kernighan and Rob Pike, about debugging

Here are some data points by way of explaining it to the teddy bear...

Temperature Deviation

After a suitable amount of time for the control system to stabilize, the extrusion head is running about 11° colder than the set point temperature when the cooling fan is enabled and 5° colder when the fan is off - at least according to the Control Panel of ReplicatorG:

Extrusion Head Temperature Deviation

| Target |

Fan

On |

Fan

Off |

| 240.0° | 229° | 236° |

| 245.0° | 234° | 240° |

| 250.0° | 239° | 245° |

Bowden Cable Loose

The Bowden cable is loose on the extruder. There's about a 1.1mm gap between the collar of the retaining ring and the plastic adapter piece. This gap can increase to 1.8mm if you pull up on the retaining ring, but then the gap isn't equal all the way around it; the other side gap reduces to 0.9mm or so.

|

| Bowden tube attachment gap. |

The assembly instructions didn't include anything about how to attach the Bowden cable to the extruder, so I just put the retaining ring on it and jammed it in. That may be the problem. How to tighten it up though?

Starting & Stopping

Using the ReplicatorG Control Panel to extrude by clicking the Motor Control 'forward' radio button when the head is up to temperature, there is about a 4 or 5 second lag before plastic starts to come out.

The extruder motor control via the Control Panel is really flakey though. There is a long lag between stopping extruding by clicking the Motor Control 'stop' radio button and when the motor actually stops turning. The longer you leave the extruder running, the longer it takes the motor to turn off when you do click 'stop'.

But, after the extruder motor really does stop, there continues to be plastic extruded for about 10 to 15 seconds afterwards. This amounts to about 7cm of extruded plastic. If this is 0.4mm diameter extrusion (it measures pretty close to that) like the nozzle says it should be, then 70mm of extra extrusion is about 8.8mm³ of plastic. This corresponds to an input length of ⌀2.94mm filament approximately 1.3mm long.

Extrusion Rate

The extruder hobbed bolt rotates at approximately 1 rpm (58 seconds for a complete revolution) when the Motor Speed (RPM) [sic] is set to 1500. When the "drive gear" in Skeinforge is set to 6.5mm diameter, 1 rpm corresponds to a radial speed of 20.4mm/min or 0.34mm/sec.

Note: At 200 steps per revolution and the gear ratio of 8:49 in the extruder, the stepper is stepping 1,288 per minute, so the 1500 number seems to be completely bogus. But the motion seems to be a series of bursts of steps with pauses in between so this may represent a target stepping rate. This is probably a firmware issue, where there is only a "subroutine" to step so-many steps, and not a continuous run subroutine.

G Code Value

What do the extruder G code units correspond to? Looking in the .gcode file, after running

a part, the absolute position of the extruder is E18151.976 with 100% fill. From the Inventor iProperties for that part, the volume is 1597.773 mm³, so that's about 0.088 mm/unit. Thus, the start.txt code of E260 would extrude 22.9mm³ of plastic or a stream about 18cm long. I guess it's that long.

Motor Speed

When starting the part with the E260 G code, the extruder gear turns not quite 70 degrees in 15 seconds, so approximately 4mm of filament, or 27mm³ of plastic, for an extrusion length of 21cm. I guess that's close enough to 18cm.